3. General & Preventive Maintenance

1.Maintenance Cautionary Notes

1.1 Important Precautions.

READ this manual before operating or servicing this equipment.

-

ALWAYS remove power and wait at least 30 seconds before connecting / disconnecting any internal harnesses. Failure to observe these precautions may result in damage to, or destruction of the equipment.

-

ALWAYS take proper precautions when handling static sensitive devices.

-

SAVE this manual for future reference.

-

DO NOT allow untrained personnel to operate, clean, inspect, maintain, service or tamper with this equipment.

-

DO NOT connect or disconnect any digital or analogue components to the equipment with power connected or damage may result.

-

Do not use any chemicals to clean this equipment, unless otherwise stated in this manual.

-

When using compressed air to blow down this equipment, do not direct the air stream at electric/pneumatic or other sensitive devices. Ensure correct PPE is used appropriately.

-

Do not wet wash any of the equipment unless stated to do so.

-

Report all defects immediately to your supervisor or manager.

-

When first installed all surfaces must be cleaned of all foreign material.

Ensure all energy sources are isolated before attempting to clean this machinery. All loose products should be gently brushed off the machine components with a small hand brush. If a vacuum system is installed for cleaning purposes use a small application head to remove loose product from this equipment.

Where applicable, follow the manufactures instructions stated in the original equipment manual. All safety warnings and cautionary advice must be observed.

Cleaning should occur at the end of each day’s production or before maintenance work. Cleaning of every station and work area on the process and line equipment is very important.

Clean with a dry lint free cloth or soft brush; use a vacuum attachment if installed.

Include cleaning for these areas:

-

All access points including guards.

-

All the floor area underneath and around the machine.

-

Sensors and switches.

-

Motors and gearbox units.

-

Pneumatic cylinders and fittings.

-

Internal and external surfaces and the dust extraction ducting including flexible tubing.

-

All product contact surfaces must be cleaned to an acceptable hygiene level.

If the product has been exposed to moisture and solidified a scraper with a hard plastic blade can be used. Under no circumstances is a metal blade scraper to be used. Once the hardened product has been removed the scraper and the cleaned area must be wiped down. Any wet areas after washing must be cleaned using a clean dry cloth. Wipe all areas afterwards using a clean dry cloth.

1.2 Personnel.

-

Only qualified personnel are permitted to operate, adjust, service or maintain `BRML' equipment.

-

Personnel are prohibited from interfering with machinery in any way when it is in operation.

1.3 Safety.

WARNING

Safety screens and covers must be maintained where fitted and replaced in the correct position after maintenance or servicing is completed.

1.4 Service, Repair & Adjustments.

-

Before servicing or repairing, stop the machine and disconnect all energy sources.

-

Maintenance and adjustments must be performed with all energy sources isolated unless otherwise specified in this manual.

-

To isolate the machinery, refer to the “warning” page in this manual.

1.5. Pneumatic Supply.

-

High pressure pneumatic systems are dangerous.

-

Do not service or troubleshoot systems with the compressed air supply on. Be sure to bleed off any trapped compressed air before working on components since it is possible to have high pressures trapped in the pneumatic or gas lines.

2.Maintenance Specifications

2.1 Pneumatic Cylinder Torques

For further information please refer to the OEM or the manufacturer.

2.2 Pneumatic System Settings.

Pneumatic Pressure – Regulator.

3. Maintenance Schedule

3.1 Magazine and Picture Frame Maintenance Schedule

3.1.1 Motors, Gearboxes, & Brakes.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Grease electric motors if required.

X

Inspect motor brake adjustments.

X

Inspect oil level.

X

3.1.2 Belts and Pulleys/Chains and Sprockets.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect for product build up

X

Inspect chain and sprockets.

X

Inspect belts and pulleys.

X

Inspect belt/chain tension

Inspect belt/chain alignment.

X

X

3.1.3 Chassis and Fasteners

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect all nuts and Bolts

X

Inspect for product build up.

X

Inspect for stress fatigue fractures

X

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

Grease linear bearings.

X

Inspect bushes.

Inspect cam tracks (If Applicable)

Inspect and Grease bearings, as applicable.

Inspect linear bearing tracks.

X

X

Inspect linear bearing bolts.

Grease spherical ball ends where applicable.

3.1.4 Bearings, Bushes and Cam Tracks.

6 Monthly

X

X

X

X

3.2 Infeed and Labelling Conveyor Maintenance Schedule

3.2.1 Bearings, Bushes and Cam Tracks.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

Grease ball bearings.

X

Inspect and Grease bearings, as applicable.

Inspect ball bearing tracks (If applicable.)

Inspect ball bearing bolts.

Grease spherical ball ends where applicable.

6 Monthly

X

X

X

X

3.2.2. Motors, Gearboxes, & Brakes.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Grease electric motors if required.

X

Inspect motor brake adjustments.

X

Inspect oil level.

X

3.2.3 Belts and Pulleys/Chains and Sprockets.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect for product build up

X

Inspect chain and sprockets.

X

Inspect belts and pulleys.

X

Inspect belt/chain tension

Inspect belt/chain alignment.

X

X

3.2.4 Pneumatic and Vacuum System

Task ID.

Inspect vacuum filters

Clean vacuum cups

Inspect all pneumatic cylinder mounts.

Clean vacuum filters

Inspect the pneumatic service unit.

Inspect valves

Test pressure and inspect sensor switch settings.

Inspect all regulators and settings.

Test all pneumatic cylinders for air leaks.

Test all pneumatic cylinders for air leaks.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

X

X

X

X

X

X

X

X

X

X

3.2.5 Chassis and Fasteners

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect all nuts and Bolts

X

Inspect for product build up.

X

Inspect for stress fatigue fractures

X

3.3. Collation Unit Maintenance Schedule

3.3.1 Bearings, Bushes and Cam Tracks.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Grease linear bearings.

X

Inspect bushes.

Inspect cam tracks

Inspect and Grease bearings, as applicable.

X

Inspect linear bearing tracks.

X

X

X

Inspect linear bearing bolts.

X

Grease spherical ball ends where applicable.

X

3.3.2. Motors, Gearboxes, & Brakes.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Grease electric motors if required.

X

Inspect motor brake adjustments.

X

Inspect oil level.

X

3.3.3. Belts and Pulleys/Chains and Sprockets.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect for product build up

X

Inspect chain and sprockets.

X

Inspect belts and pulleys.

X

Inspect belt/chain tension

Inspect belt/chain alignment.

X

X

3.3.4 Chassis and Fasteners

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect all nuts and Bolts

X

Inspect for product build up.

X

Inspect for stress fatigue fractures

X

3.4 Pick Head Maintenance Schedule

3.4.1 Pneumatic and Vacuum System

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect vacuum filters

X

Clean vacuum cups

X

Inspect all pneumatic cylinder mounts.

X

Clean vacuum filters

X

Inspect the pneumatic service unit.

X

Inspect valves

X

Test pressure and inspect sensor switch settings.

X

Inspect all regulators and settings.

X

Test all pneumatic cylinders for air leaks.

X

Test all pneumatic cylinders for air leaks.

X

3.4.2 Fasteners

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect all nuts and Bolts

X

Inspect for product build up.

X

Inspect for stress fatigue fractures

X

3.5. Scanner System Maintenance Schedule

Task ID

Daily

Weekly

Monthly

3

Monthly

6

Monthly

Clean lens before every assignment or whenever needed

Clean lens by putting cleaning fluid on lens tissue and use a circular motion to wipe the lens from the center to the outer edge

Maintain tripod and camera body before and after every use.

X

X

X

3.6. Enclosure Maintenace Schedule.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Clean photo eyes, reflectors and proximity sensors

X

Inspect the fan filter in control console (if fitted).

X

Inspect proximity switch adjustments.

X

Inspect reed switches.

X

Inspect mechanical switches.

X

Inspect the PLC battery indicator.

X

Inspect the PLC battery indicator.

X

Inspect all other switches and buttons.

X

Test 24-volt DC supplies for adjustment.

X

All cabinet wiring shall be inspected prior to power up

X

X

Random ferrule tagging visual check, should be clear and readable

Random Point to Point (resistance test)

X

Random Point to Ground (resistance test)

X

Earth bonding test shall not execute 0.1 ohms between bounded item and earth bus bar, use megger to check earthing

X

Randomly check the wiring for proper crimping & termination (Tug test)

X

Check the cabinet are connected to a suitable earthing point in the FAT premise

X

Check all MCB's for the correct rating protection (refer to Electrical Drawing)

X

Switch ON circuit breaker 'MCB', check voltage on its output terminals.

X

Ensure no alarm on the IO modules after power up of the 24V DC field power supply

X

For each type of power feed, measure voltage & total system current with system "No-Load" condition and record the results

X

3.7. Taping Machine Maintenance Schedule

3.7.1 Bearings and Bushes

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Grease linear bearings.

X

Inspect bushes.

Inspect and Grease bearings, as applicable.

X

Inspect linear bearing tracks.

X

X

Inspect linear bearing bolts.

X

Grease spherical ball ends where applicable.

X

3.7.2. Motors, Gearboxes, & Brakes.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Grease electric motors if required.

X

Inspect motor brake adjustments.

X

Inspect oil level.

X

3.7.3. Belts and Pulleys/Chains and Sprockets.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect for product build up

X

Inspect chain and sprockets.

X

Inspect belts and pulleys.

X

Inspect belt/chain tension

Inspect belt/chain alignment.

X

X

3.7.4 Chassis and Fasteners

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect all nuts and Bolts

X

Inspect for product build up.

X

Inspect for stress fatigue fractures

X

3.7.5 Pneumatic System

Task ID.

Inspect vacuum filters

Inspect all pneumatic cylinder mounts.

Clean vacuum filters

Inspect the pneumatic service unit.

Inspect valves

Test pressure and inspect sensor switch settings.

Inspect all regulators and settings.

Test all pneumatic cylinders for air leaks.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

X

X

X

X

X

X

X

X

3.7.6 Cutter Blade

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Blade Inspection

X

Blade Replacement

X

Cleaning and Lubrication

X

Tightening Check

X

3.7.7 Roller

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Roller Adhesive Check

X

Roller Movement Check

X

Roller Replacement

X

3.8. Palletizer Infeed Roller Conveyor Maintenance Schedule

3.8.1 Bearings

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect and Grease bearings, as applicable.

X

Inspect bearing pocket.

X

3.8.2. Motors, Gearboxes, & Brakes.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Grease electric motors if required.

X

Inspect motor brake adjustments.

X

Inspect oil level.

X

3.8.3. Chains and Sprockets.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect for product build up

X

Inspect chain and sprockets.

X

Inspect belt/chain tension

Inspect belt/chain alignment.

X

X

3.8.4 Chassis and Fasteners

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect all nuts and Bolts

X

Inspect for product build up.

X

3.8.5 Roller

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Roller Adhesive Check

X

Roller Movement Check

X

Roller Replacement

X

3.9. Cobot/Robot Maintenance Schedule.

Task ID.

Daily.

Monthly.

3 Monthly

6 Monthly

Check for abnormal noise or vibration

X

Inspect cables & connectors

X

Clean exterior and clear debris

X

Check joint movement for smoothness

X

Inspect base & bolts for tightness

X

Test emergency stop & safety devices

X

Inspect teach pendant & cable

X

Clean the fan and ventilation grilles (if accessible).

X

Ensure brakes hold position properly (if applicable).

X

Open the controller (if safe and authorized) to check for dust buildup, loose wiring, or signs of overheating.

X

X

Test battery voltage levels and condition (especially for absolute encoder batteries).

Look for signs of wear or cracking on the arm or base.

X

Inspect end-of-arm tooling (gripper, welder, etc.) for stability and alignment.

X

Verify that collaborative mode limits (force, speed, etc.) are functioning correctly.

X

Backup robot data and settings.

X

Ensure cooling fans are working properly.

X

Replace the battery in the robot controller (if applicable).

X

Annual

3.10 Case Erector Maintenance Schedule

3.10.1 Bearings, Bushes and Cam Tracks.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

Grease linear bearings.

X

Inspect bushes.

Inspect cam tracks

Inspect and Grease bearings, as applicable.

Inspect linear bearing tracks.

X

X

Inspect linear bearing bolts.

Grease spherical ball ends where applicable.

6 Monthly

X

X

X

X

3.10.2. Motors, Gearboxes, & Brakes.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Grease electric motors if required.

X

Inspect motor brake adjustments.

X

Inspect oil level.

X

3.10.3 Belts and Pulleys/Chains and Sprockets.

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect for product build up

X

Inspect chain and sprockets.

X

Inspect belts and pulleys.

X

Inspect belt/chain tension

Inspect belt/chain alignment.

X

X

3.10.4 Pneumatic and Vacuum System

Task ID.

Inspect vacuum filters

Clean vacuum cups

Inspect all pneumatic cylinder mounts.

Clean vacuum filters

Inspect the pneumatic service unit.

Inspect valves

Test pressure and inspect sensor switch settings.

Inspect all regulators and settings.

Test all pneumatic cylinders for air leaks.

Test all pneumatic cylinders for air leaks.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

X

X

X

X

X

X

X

X

X

X

3.10.5 Chassis and Fasteners

Task ID.

Daily.

Weekly.

Monthly.

3 Monthly

6 Monthly

Inspect all nuts and Bolts

X

Inspect for product build up.

X

Inspect for stress fatigue fractures

X

3.11. Label Applicator Maintenance Schedule.

Task ID.

Daily.

Monthly.

3 Monthly

6 Monthly

Clean the touch screen by wiping with a dry soft cloth or cotton pad.

X

Clean the Printhead with pre-soaked swabs or wipes (To maintain maximum print quality, clean the printhead every time the ribbon is changed)

X

Clean the Print Roller with pre-soaked swabs or wipes

X

Clean external surfaces

X

Clean the sensor lens with a soft cloth.

X

Check all screw-fastened plug-and-socket connectors for tight fit.

X

Weekly.

4. Maintenance Procedures

4.1. Bushes and Cam tracks.

4.2. Pneumatic Service Units.

4.3 Belts and Pulleys/Chains and Sprockets.

4.4 Drive Belt Tension.

Fig 1

4.5 Chain Tension.

4.6 Pneumatic Cylinders.

4.7 Pneumatic Cylinder Mounts.

Inspect the clevis pins, trunnions and rod ends for excessive wear – report all defects to your supervisor.

4.8 Chassis and Fasteners.

4.9 Photo Electric Sensors.

Note: Click on the Image for the Manual

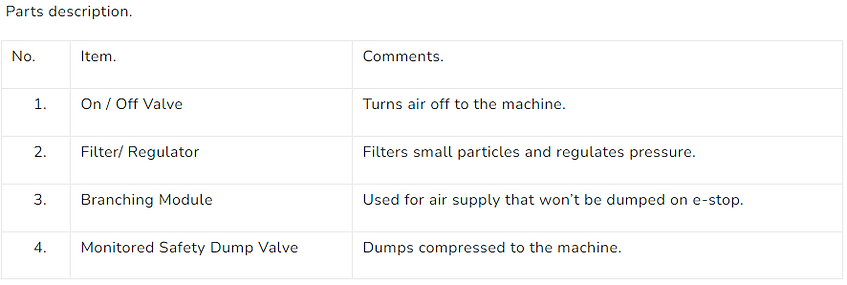

4.10 Pneumatic Energy System.

4.11 PLC Battery Check.

4.12 Fan Filter.

Inspect the fan filter in MCC cabinet every month.

4.13 Vacuum Filters and Valves.

4.14 Vacuum Cups

4.15 Pneumatic Service Units.

For default pneumatic settings, please refer to “Maintenance Specification” in section 4.2.

5. Lubrication System

A lubrication system is a critical component of any machinery that relies on the movement of mechanical parts. The purpose of a lubrication system is to provide lubrication or oil to the various moving parts of gears or machinery to reduce friction and wear and tear, prevent overheating, and increase the lifespan of the machinery.

Please refer the below lubrication schedule

5.1 Chain

5.2 Bearings

5.3 Gear Motor / Gearbox

6. Maintenance Drawing

Click on the below Assemblies for the Maintenance Drawings